Who is your customer?

The Customer is taking the driver seat. But: who exactly is your Customer?

If you want to be successful in your business you have to provide your customer products and services that could be sold to him. You have to solve problems the customer has right now, or helping him to feel better according to his very specific expectations.

So it seemed to be very easy for a company or organization to identify and know their customer. I hate to put the brakes on, but it’s not that simple. They’re observing, sharing information, and influencing others … about your products, services, and your brand. They are, in fact, deciding with every interaction whether or not they want to be your loyal customer.

But let’s dig in a theoretical approach on this, just imagine that you would know very well what to do to solve a actual problem your customer has. A thought experiment.

Experiment, Part 1: Keeping your customer in mind all times

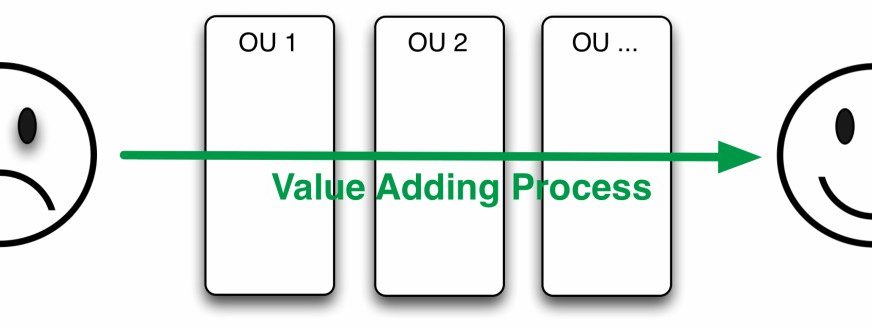

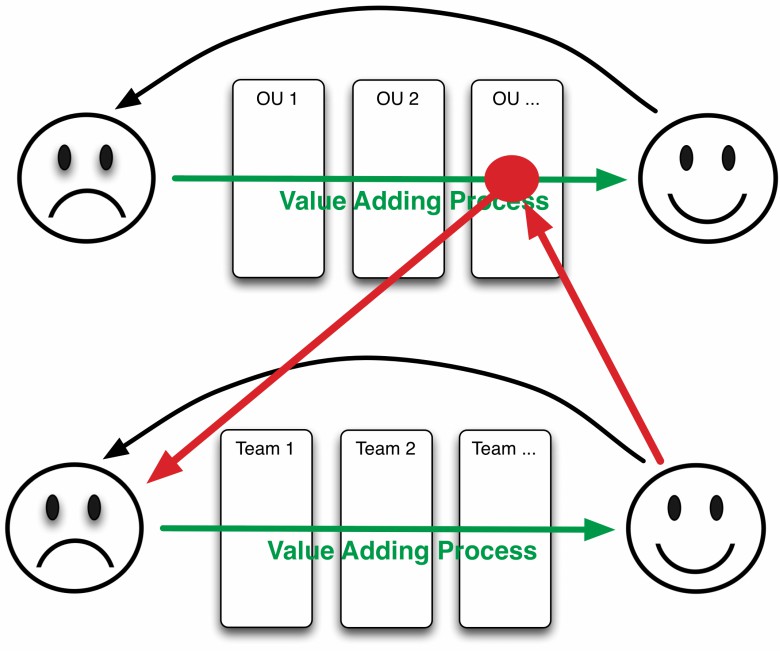

When your brand does things right, you’ve excited the shopper and loyalty has been secured. So as a first step let us create a picture showing the “value generating” way from your customer having his problem (on the left) to being solved by a product or service delivered by your company (Fig. 1.1):

Fig. 1.1: The value adding process: make your customer smile

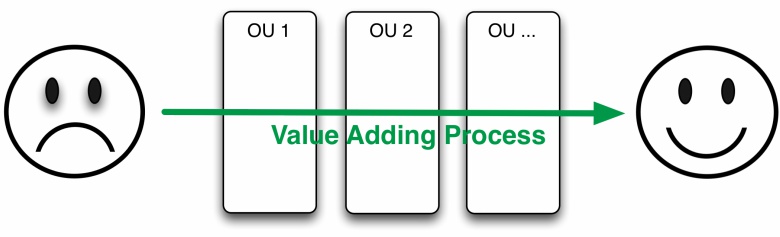

First problem you will have to face is that this way through your company is based on the work of different departments / organizational units, maybe starting with marketing/sales, then needing some activity of the production floor, finance, controlling, delivery unit, etc. Today we regularly discuss about “crossing the silos”, but all this units have to work focused on the product this company has to deliver, not on the unit (silo) success itself (Fig. 1.2):

Fig. 1.2: Crossing siloes

The Silo Mentality

The silo mentality is really an organizational way of thinking: they create an environment of individual and disparate systems within an organization: „Organizational silos typically do not share the same priorities, goals or even the same tools, so departments operate as individual business units or entities within the enterprise“[1] So be aware of different priorities, responsibilities and vision. Often, managers do have no knowledge of the priorities and goals of other departments and there is little communication, collaboration and teamwork between these business units.

When Siloes are the problem

Today, managers are tasked to break the silo mentality to ensure information and production flows freely between all departments in an organization. Communication and collaboration is essential breaking down the silo mentality.

You will have to follow the ideas of Lean Production, over all the industrial and business processes you have today. Especially the IT Organization loves to raise their agile approach at this time. Ok, this is a very lean approach that has a serious focus on the customer (we will have to discuss later who may be the customer of this supporting IT unit) and communicates closely with people having a problem that should be solved. But on the other hand agile is only a helping method to become more customer-focused, to be lean. How to spread this idea over all organizational units of your company?

Try to establish lean processes “end-to-end” covering the way shown in Fig. 1.2 totally. This is a major change in company culture and also a change for all the people working in the organization. So it is not only the need to gain an understanding of your customers – knowing who they are, what matters to them and how they want to do business consistently and long-term – every unit of your organization has to understand what their part of this knowledge is.

Improve products, services and processes continual

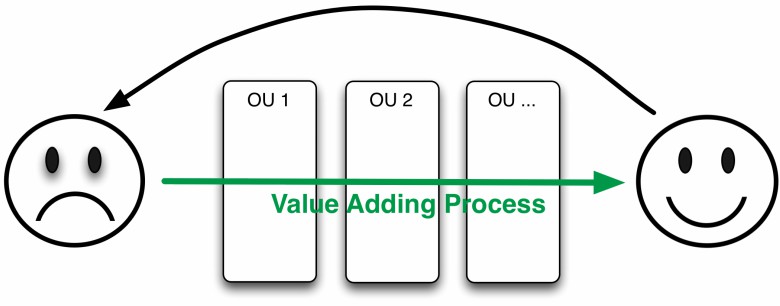

And you will have to add something import more: if you have successful implemented lean culture in your organization you will have to improve this again and again, always accepting that your customer is really on the driver seat! So you need to implement processes of a continuous improvement, including all parts of your company and always focusing the customer (Fig. 1.3): the delivery of (customer valued) processes are constantly evaluated and improved in the light of their efficiency, effectiveness and flexibility.

Fig 1.3: Continuous Improvement

Based on my personal experience it is very important to follow the Kaizen (the translation of kai (“change”) zen (“good”) is “improvement”) ideas at this point, e.g.: „Improvements are based on many small changes rather than the radical changes that might arise from Research and Development“ (Wikipedia). Also this is part of an industrial, a lean approach.

Second step of this experiment: trying to be lean and following the ideas of the Theory of Constraints[2] you will have to identify bottlenecks and to solve some delays on the way through your organization: a constraint is anything that prevents the system (= organization) from achieving its goal.

You have to speed up the Work in Progress (WiP)[3] as fast as possible. So all problems on the way have to been solved.

Kanban WIP Limits

Limiting the amount of Work in Progress can help your organizational units to keep a steady pace and make sure no one is ever overwhelmed. Work in Progress Limits will help you manage and achieve a good workflow. This is the core property Kanban: Work in Progress is limited! Make it visible using a Kanban Board. As a fan of Jim Benson and Tonianne DeMaria Barry’s Personal Kanban[4] writings, you’ll know that they have two basic rules:

- Visualize your work

- Limit your Work in Progress

Experiment, Part 2: Do your organizational units know their customers?

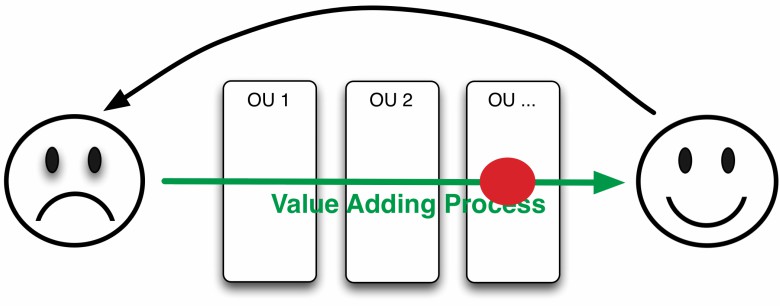

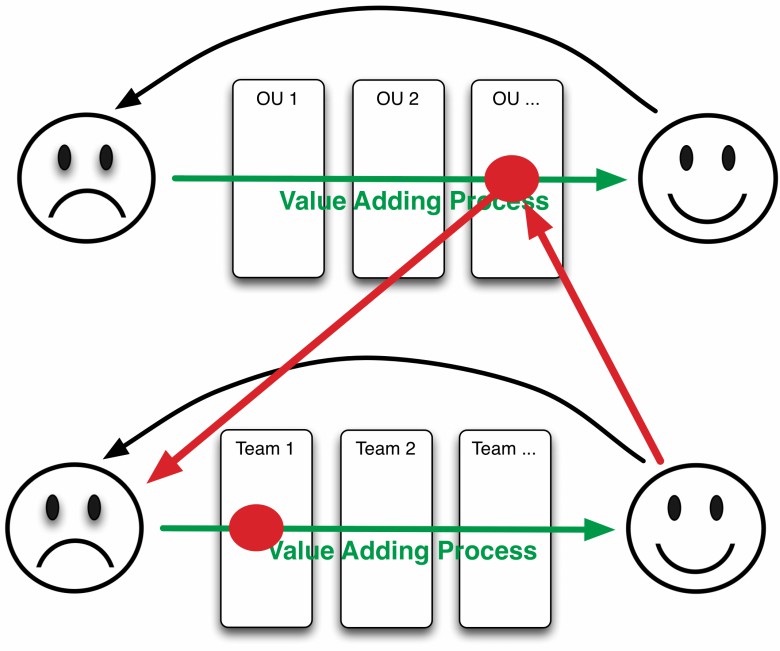

Now, just to continue in our experiment, imagine that one of your units may have a problem giving such a delay (Fig. 1.4):

Fig 1.4: Organizatorial Unit having a problem

Hopefully you will have a unit that may help this unit on the way from having a problem to be happy that it is solved. So the customer of this helping unit is the unit having this problem (Fig 1.5):

Fig 1.5: Customer of this helping unit is the unit having this problem

How to manage this? In a traditional way manager of both units will have a conference, discussing the problem and ideas how to solve and after that going back to their units explaining them what to do. That isn’t lean. Why are the specialists of both units are not in contact directly? You have to avoid translating misunderstandings and to save time while getting better and faster results? So supporting organizational units will have over units of this company as a customer. And they have it to handle in a lean way too. If they are focused to solve customer problems they would not need management activities to go through their daily work. The supporting teams will change to a customer-focused, self organizing structure without the need of additional lead.

But they need rules and company directives to organize. So this will only be successful with deep knowledge of the company customer (refer to part 1 of this experiment) and company specific rules.

Experiment, Part 3: Nothing to do for the management?

And what is about the management in this customer-focused organization? Let’s have step three of this experiment: who has to work on problems that supporting teams might have on their WiP to get their customers happy (Fig. 1.6)?

Fig. 1.6: Who has to work on problems of a supporting team?

Manager have to give support at this moment, but in an organizational way – the team has better knowledge about his work as anyone else, especially more than a manager can have. So management’s customer is the team. And also they have a way from the unhappy customer to the happy one. This would require to work together to cover all the management areas (Fig. 1.7):

Fig. 1.7: Management’s customer

Also company specific rulesets are to be defined by the management, as well as the working on financial aspects and deciding about the company organization. They have to create activities to change company culture, and this is a very long and difficult way to go. Only now it makes sense to talk about the digital transformation: it is change of culture and will create a new organization that might differ very much from all established processes and management structures you might have today.

First accept that all organizational units must know their customer, as well as the company itself. Customers are always in the driver seat. So communicate directly and improve processes continuously.

[1] http://www.webopedia.com/TERM/I/information_silo.html, 22.06.17

[2] The Theory of Constraints (TOC), by Eliyahu M. Goldratt, is a management paradigm that views any manageable system as being limited in achieving more of its goals by a very small number of constraints. There is always at least one constraint, and TOC uses a focusing process to identify the constraint and restructure the rest of the organization around it. TOC adopts the common idiom „a chain is no stronger than its weakest link.“ This means that processes, organizations, etc., are vulnerable because the weakest person or part can always damage or break them or at least adversely affect the outcome (Wikipedia).

[3] Work in progress (WIP, also called work in process): Lean production principles consider excess WIP to be an indicator of waste caused by bottlenecks in the (manufacturing) process or an unstable supply chain. Too much work in progress is undesirable because it ties up money that could be generating higher returns somewhere else in the company (Wikipedia).

[4] Refer to: http://www.personalkanban.com/pk/author/jim-benson/